Cylindrical grinding is considered a leading process in the preparation of high-precision parts in the world of precision engineering. It finds application in the making of molds, dies, and machine parts. It requires both expensive machinery and commitment to quality, craftsmanship, and continual improvement to achieve the micron level of accuracy. Being a special producer, Langdi Precision has established itself as a solid leader in ultra-precision grinding of cylindrical parts. A combination of high-tech, strict quality control, and decades of experience, Langdi Precision has continued to match the quality tolerances required by present-day industries. When customers ask what is cylindrical grinding, Langdi Precision explains that it’s a process designed for achieving perfect roundness and surface accuracy.

Adherence to Micron-Precision

The skills of Langdi Precision are in its capability to make pieces with a very small level of tolerance, like 0.001mm in true roundness and 0.002mm in machining accuracy. This degree of accuracy is not the mere feat of technical accomplishment; it is the work of understanding material behavior, grinding relationships, and process stability. Cylindrical grinding processes involve many steps of setting up and final checking, and each step is strictly followed to make sure that the parts are produced to the precise specification. Such commitment to precision has enabled Langdi to cater to any industry that requires high precision, such as mold production, electronics, and high-performance equipment.

State-of-the-art Grinding Services

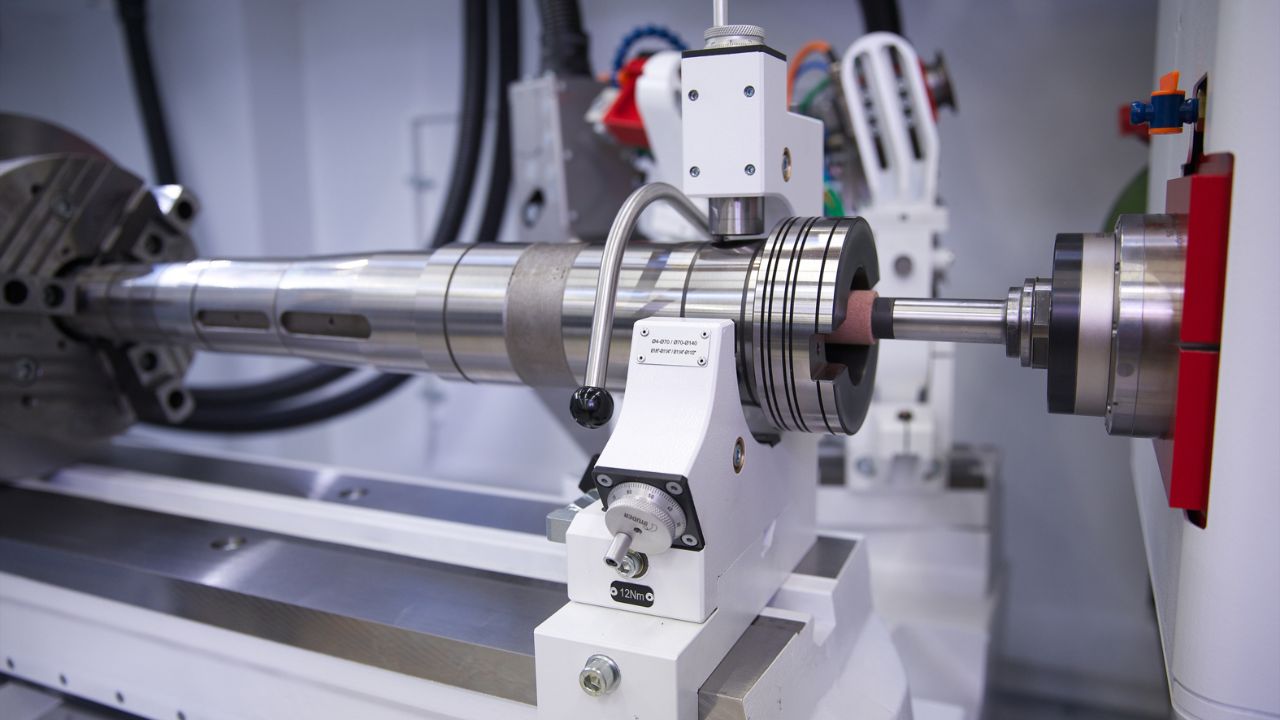

The ability of the company to have all the grinding technologies is its strength. Langdi Precision deals with centerless and cylindrical grinding, internal and external grinding. The centerless grinding process also obtains a high level of surface roughness within Ra 0.05mm, and the roundness is also fine as 0.001mm. In terms of the internal and external cylindrical grinding, Langdi has a processing scope of up to 320mm, and in this case, it is flexible to the components of any size.

This degree of accuracy is achieved by using high-performance machines, which are procured under the leading brands around the world. The products of the factory are outer and inner diameter grinders, CNC lathes, as well as the optical curve grinders of both Japan and Taiwan. Combined with efficient, repeatable, and error-free results, these machines, together with the skilled technicians of Langdi, allow the production of large and small quantities of products with efficiency.

Integration of Advanced Inspection Equipment

It is not possible to overcome ultra-precision without having the same sophisticated inspection capabilities. The metrology section of Langdi Precision has the best state-of-the-art instruments that belong to the world-renowned brands like Nikon, TRIMOS, and Rational. The company operates height gauges, projectors, and 2.5D measuring tools that have accuracies up to 0.001mm. Each element will be carefully checked so that the end product will comply with the specifications of the customers.

This adherence to metrological verification makes Langdi different from any normal machining shop. The company ensures complete control over the consistency and quality by applying accurate measurement instruments at all production processes to minimize deviations and increase the reliability of the final product of each component.

Experienced Team and Technical Expertise

Whereas capability is characterized by equipment, excellence is characterized by expertise. The engineering team at Langdi Precision is a combination of years of experience in machining of mold components, CNC turning, and fine grinding operations. Their technicians are well-trained on the use of Japanese and Taiwanese grinding systems and also understand very well the interplay of machine parameters, material properties, and surface integrity.

This is because of the constant aim of the team to achieve perfection, and this guarantees that every project enjoys technical accuracy and professionalism. This experience enables Langdi to fabricate tailored solutions for customers with tight tolerances and complicated geometries.

Comprehensive Manufacturing Environment

The Langdi Precision facility is determined to be efficient and precise. It also uses high-speed CNC machining, wire EDM, optical profile grinding, and precision surface grinding under one roof. This eases the overall coordination of the different manufacturing processes, thus minimizing the lead times without compromising on the quality of the product.

It is also confirmed that the company adheres to the international standards of quality as a result of the ISO9001: 2015 certification of the company. All the production operations, such as the management of the raw material and final inspection, are designed within a quality management system, which is targeted at establishing uniformity and traceability.

Conclusion

The success of Langdi Precision in the ultra-precise cylindrical grind approach can be attributed to a strong blend of robust technology, the best inspection systems in the world, and a highly trained workforce dedicated to perfection. Its capacity to retain tolerances on microns continuously distinguishes it in the sphere of precision machining. The steadily increasing accuracy and reliability in component production by industries keep placing Langdi Precision as an example of excellence; it demonstrates that precision is not only a goal, but a culture that is present in all facets of its operation.