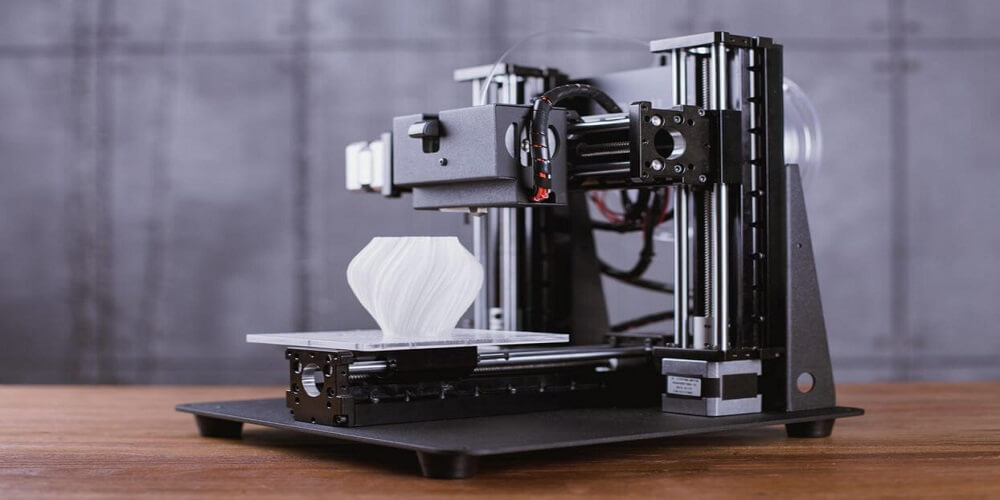

3D printers have exploded in popularity because it has provided a reliable solution to the traditional manufacturing processes which takes a lot of time. Many industrial 3D printing companies adopt this product development method because of the sophisticated functionalities and technology integrated with the printer to deliver accurate and final quality results. The following are the key features that you should look into when you plan to invest in the industrial-grade 3D printer.

Prints engineering materials and higher performance

Industrial 3D printers are used exceptionally for materials used in the manufacturing industry because of their mechanical properties and unique functions. They are designed to offer specific requirements for high-performance materials, especially those reinforced with carbon fiber. These materials require a temperature of above 170C to produce the desired mechanical resistance and correct dimensions.

Large heat chamber

The industrial 3D printer contains a large chamber with adequate workspace to print high-performance materials. When you purchase the industrial printer, it is essential to check the dimensions to ensure that it accommodates and offers enough workspace for creating parts of different objects at once. The inner part of the industrial 3D printer should have critical parameters, mainly the metal parts that are dedicated to withstand high temperatures.

High print speed

The rate of printing relates to the high performance of the industrial 3D printer. If you compare this printer with commercial 3D printers, you will actually notice the difference in quality and print speed. Companies that have adopted this 3D printing technology demonstrate high productivity and accuracy. Similarly, they tend to produce more objects hence lowering the overall printing costs.

It contains a dual extruder system.

Since the industrial 3D printer performs most high-performance engineering tasks, it contains a dual extruder system to prevent printing failure. The materials used for printing are expensive and require high mechanical resistance, which is why the dual extruder system is integrated with the printer to provide soluble support for the entire printing process.

Complete ecosystem

The industrial 3D printer is capable of performing huge tasks within a strict timeline. The equipment can create many parts at once and assemble all the designated tasks without any failure. It provides an ideal solution to prevent the huge number of steps that are involved with the traditional product development methods. Therefore, you can put together various components and expect flawless and accurate prints if you don’t have time to do multiple experiments.

Safety

In the process of 3D printing, the materials usually burn at high temperatures of above 180C. The nozzle and chamber can be risky at extreme temperatures. However, the industrial 3D printer comes with a filtration system to prevent hazardous fumes from affecting the surrounding environment or your health. Further, the enclosure locks itself automatically once you initiate the print process.

Maintenance

The maintenance costs of the industrial 3D printers are not complex because it comes with auto-calibration procedures that help reduce time spent to set up and run it. The software used to control the print and other tasks comes with a user-friendly interface to cut the time needed to upload any design. Generally, the machine does need complex maintenance, especially for critical components.